In the world of modern healthcare, precision is more than a requirement it’s the foundation of every successful medical procedure. From delicate neurosurgery to routine general operations, even the smallest error can affect patient outcomes. That is why surgical instruments are not just tools; they are lifelines in the hands of skilled surgeons. At Solatch Sons, we recognize this responsibility and make precision the cornerstone of everything we design and manufacture.

Why Precision Matters in Surgery

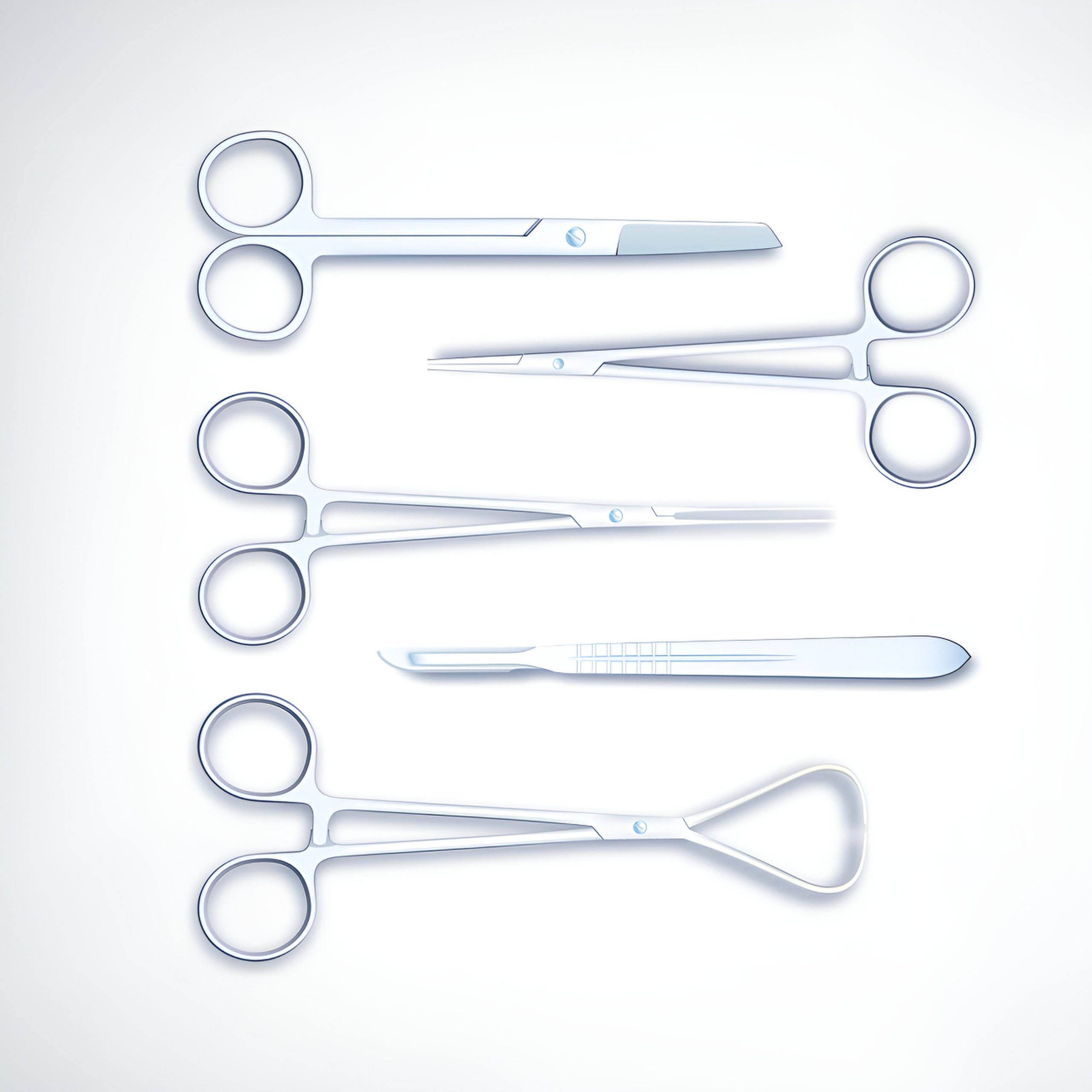

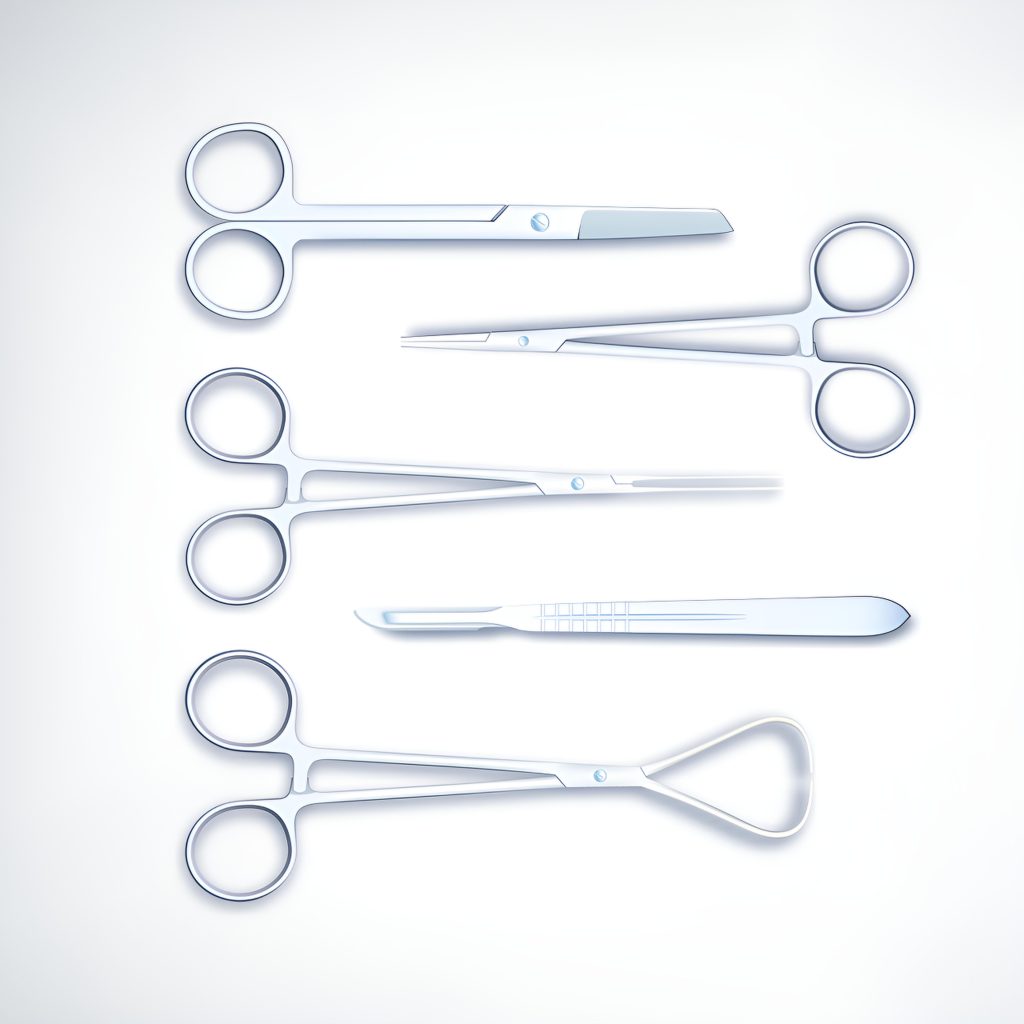

Surgical instruments serve as the extension of a surgeon’s hands. A scalpel that cuts smoothly, a forceps that grips firmly without slipping, or scissors that glide effortlessly through tissue all these details can significantly influence the accuracy and safety of a procedure. Precision ensures:

- Better surgical control: Surgeons can perform with confidence when instruments respond exactly as expected.

- Reduced risk of complications: High-quality, precise instruments minimize tissue trauma and speed up recovery.

- Consistency in performance: Standardized precision means the same results are achieved every time.

For Solatch Sons, maintaining precision is not just a technical requirement; it is part of our ethical responsibility towards patients and healthcare providers worldwide.

Craftsmanship Meets Technology

Our manufacturing process blends traditional craftsmanship with modern technology. Skilled technicians inspect and finish each instrument with care, while advanced CNC machines and laser cutting systems bring unmatched accuracy to the production line. This combination ensures that every piece we produce from surgical scissors to bone instruments meets international standards of precision.

Moreover, we invest continuously in research and development to refine our processes. Whether it is upgrading our machinery or adopting innovative polishing and coating techniques, our goal remains the same: to deliver instruments that surgeons can trust in the most critical moments.

Rigorous Testing and Quality Checks

At Solatch Sons, precision is validated through rigorous testing at every stage of production. Instruments undergo dimensional accuracy checks, performance evaluations, and durability tests before reaching our clients. By following strict international quality standards such as ISO and CE certifications, we guarantee that our instruments consistently deliver reliability in operating rooms around the world.

Serving Healthcare Beyond Borders

Our commitment to precision extends beyond manufacturing. By supplying our products to hospitals, clinics, and distributors across Europe, the USA, the Middle East, and beyond, we help healthcare providers improve surgical outcomes on a global scale. Every instrument leaving our factory carries not only our brand name but also a promise of excellence, safety, and trust.

Final Thoughts

Precision is not an option in surgery, it is a necessity. At Solatch Sons, we take pride in producing surgical instruments that embody this principle. By combining technology, craftsmanship, and strict quality assurance, we ensure that every instrument empowers surgeons to perform with confidence and care.